Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

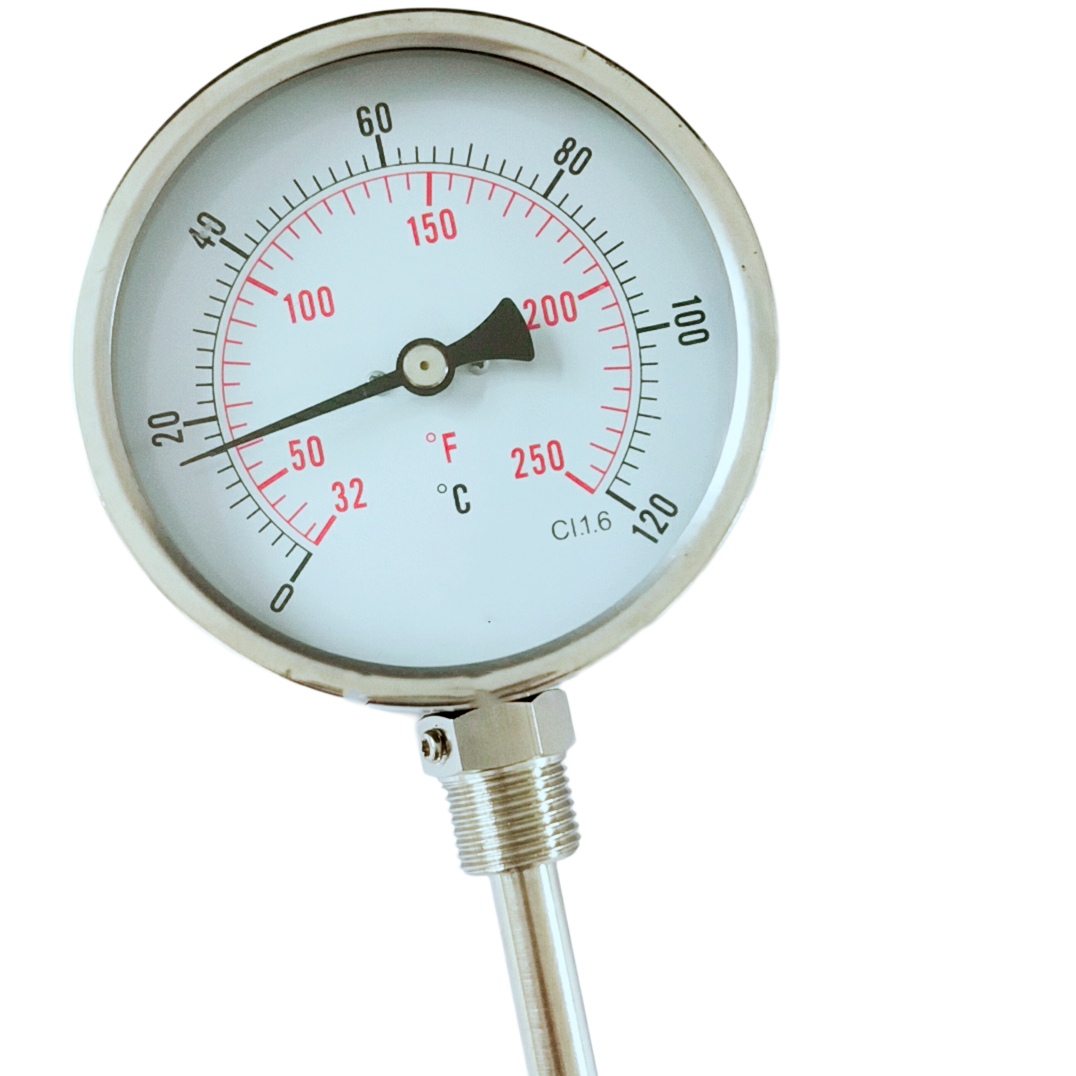

Pipe Thermometer

-

0.00 ~ 0.00/

1/ (Min. Order)

A pipe thermometer is a device used to measure the temperature of fluids (liquids or gases) flowing inside a pipe. These thermometers are essential in various industries, including HVAC, chemical processing, oil and gas, food production, and plumbing.

Types of Pipe Thermometers:

1.Insertion/Probe Thermometers

① A temperature probe is inserted into the pipe through a thermowell (a protective sleeve) or a drilled hole.

② Common types: RTD (Resistance Temperature Detector), Thermocouple, Bimetallic thermometer.

③ Used in high-pressure or high-temperature applications.

2.Surface-Mounted Thermometers

① Attached to the external surface of the pipe using adhesive or clamps.

② Less accurate than insertion types but non-invasive.

③ Often used in HVAC and low-precision applications.

3.Infrared (IR) Thermometers

① Non-contact devices that measure pipe surface temperature using infrared radiation.

② Useful for quick checks but affected by pipe material and external conditions.

4.Dial Thermometers (Bimetallic or Liquid-Filled)

① Mechanical thermometers mounted on pipes via a stem or threaded connection.

② Common in industrial and plumbing applications.

5.Digital Thermometers with Clamp-On Sensors

① Use a sensor clamped onto the pipe for quick readings.

② Often battery-powered with a digital display.

Key Features to Consider:

•Temperature Range – Ensure the thermometer can handle the fluid's temperature.

•Accuracy – Critical for process control (e.g., ±1°C or better).

•Installation Method – Insertion, surface-mount, or non-contact.

•Material Compatibility – Stainless steel, brass, or plastic for corrosive fluids.

•Response Time – Faster for dynamic processes.

•Output Options – Analog dial, digital display, or data logging.

Common Applications:

•Monitoring steam lines in power plants.

•Checking chilled water in HVAC systems.

•Measuring oil/gas temperatures in pipelines.

•Ensuring food safety in processing plants.